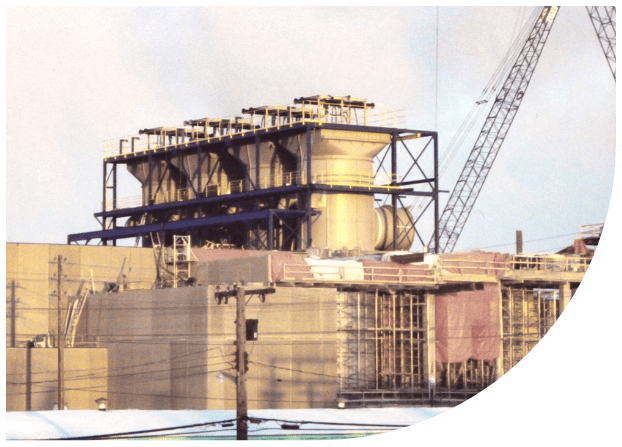

Dynamic Wall

Cooling Towers

In the Electrolyte & Slurry Cooling production of Cobalt, Copper, Nickel and Zinc metals from acid solutions, electrolyte must be cooled prior to its re-introduction to the production cells.

Cooling towers rely on intimate contact of cooling air and the electrolyte. This presents certain challenges such as: wall wetting, build-up on the walls, poor cooling efficiencies and high drift losses. Desom has developed the Dynamic Wall Cooling Tower (DWCT) which solves the problems associated with traditional designs.

Our cooling towers are also designed to handle various types of slurries that are present throughout hydrometallurgical processes.

Our unique features include:

- Base Construction which includes sludge collection and the necessary overflows and clean-out drains as an integral part of the cooling tower. This eliminates the need for acid-proof weirs constructed outside of the tower.

- Dynamic Wall Construction uses air to re-entrain the electrolyte which would normally adhere to the tower walls. This reduces maintenance and increases cooling efficiency.

- Round Cross Section provides for more uniform contact between the cooling air and the electrolyte. This increases the efficiency due to improved air-to-droplet contact.

- Demisters eliminate electrolyte droplet carry over thereby keeping emissions within regulatory limits.

- Serviceability is simplified by allowing access from outside the tower at one location.

- Self-Cleaning is accomplished by a system of water sprays which clean the mist eliminators, thereby reducing maintenance requirements.